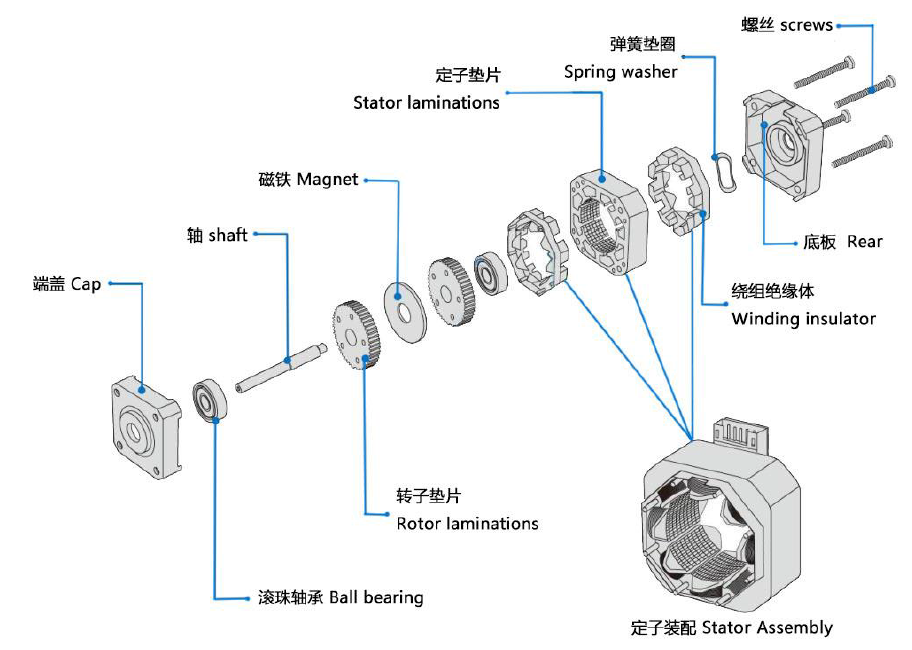

Stepper lub cev muaj zogyog ib qho khoom siv electromechanical uas ncaj qha hloov hluav taws xob pulses mus rau hauv cov cuab yeej siv tshuab. Los ntawm kev tswj cov kab ke, zaus thiab tus naj npawb ntawm cov hluav taws xob pulses siv rau lub cev muaj zog coil, stepper lub cev muaj zog lub kauj, ceev thiab tig lub kaum sab xis tuaj yeem tswj tau. Qhov tseeb txoj hauj lwm thiab kev tswj ceev tuaj yeem ua tiav yam tsis muaj kev siv lub kaw lus tawm tswv yim tswj qhov system nrog kev paub txog txoj hauj lwm, siv qhov yooj yim, tsis tshua muaj nqi qhib-loop tswj system nrog lub tshuab stepper thiab nws cov neeg tsav tsheb nrog.

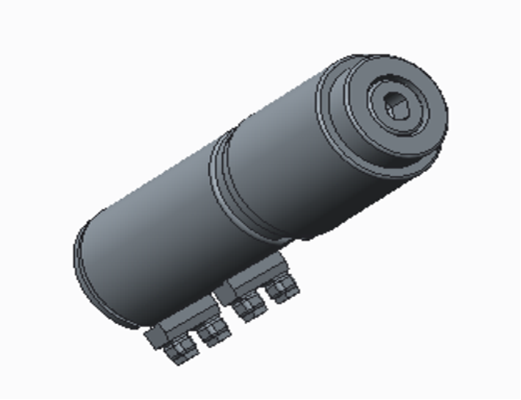

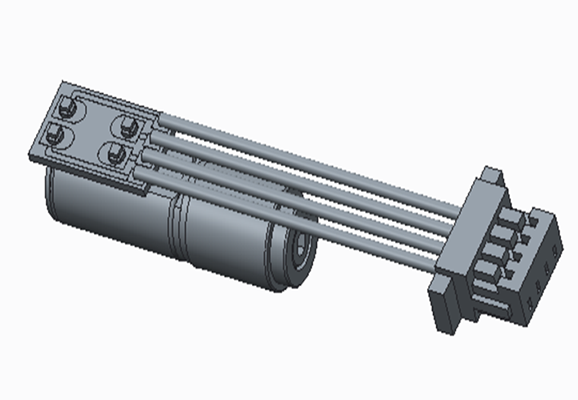

Raws li tus actuator,stepper lub cev muaj zogyog ib qho ntawm cov khoom tseem ceeb ntawm mechatronics, uas yog dav siv nyob rau hauv ntau yam automation tswj systems. Nrog rau txoj kev loj hlob ntawm microelectronics thiab precision manufacturing technology, qhov kev thov rau stepper motors yog nce nyob rau hauv ib hnub twg, thiab stepper motors thiab gear kis mechanism ua ke rau hauv ib tug txo gearbox, tab sis kuj nyob rau hauv ntau thiab ntau daim ntawv thov scenarios pom, niaj hnub no me me thiab txhua leej txhua tus ua ke kom nkag siab txog hom kev txo cov iav kis tau tus mob mechanism.

Yuav ua li cas stepper motors decelerate?

Stepper lub cev muaj zog raws li kev siv dav siv, dav siv tsav lub cev muaj zog, feem ntau yog siv nrog cov khoom siv deceleration kom ua tiav cov txiaj ntsig zoo tshaj plaws; thiab stepper lub cev muaj zog feem ntau siv deceleration cov cuab yeej thiab txoj kev, xws li txo cov iav kem, encoder, xws li, mem tes teeb liab, thiab lwm yam.

Pulse signal deceleration:stepper lub cev muaj zog rotation ceev, yog raws li qhov kev hloov ntawm lub input mem tes teeb liab hloov. Nyob rau hauv txoj kev xav, muab tus tsav tsheb mem tes, lub stepper lub cev muaj zog tig lub kaum sab xis (subdivision rau lub kaum sab xis subdivision). Nyob rau hauv kev xyaum, yog hais tias lub pulse teeb liab hloov sai heev, lub stepper lub cev muaj zog vim lub internal damping nyhuv ntawm lub rov qab hluav taws xob muaj peev xwm, lub sib nqus teb ntawm lub rotor thiab stator yuav tsis ua raws li cov kev hloov nyob rau hauv cov hluav taws xob teeb liab, yuav ua rau thaiv thiab poob cov kauj ruam.

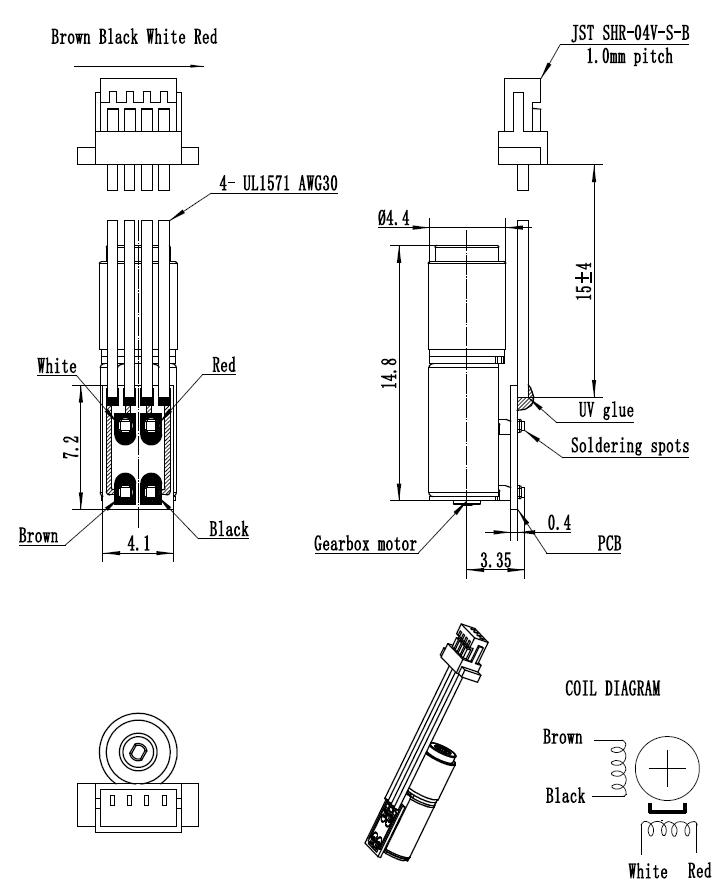

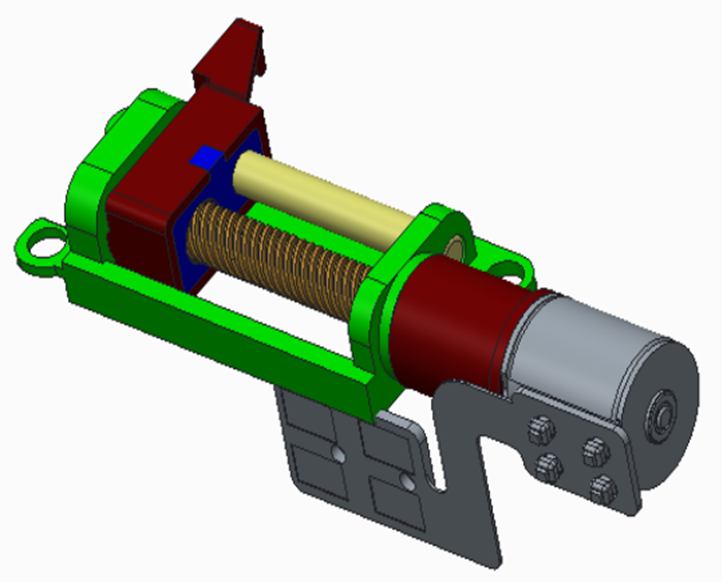

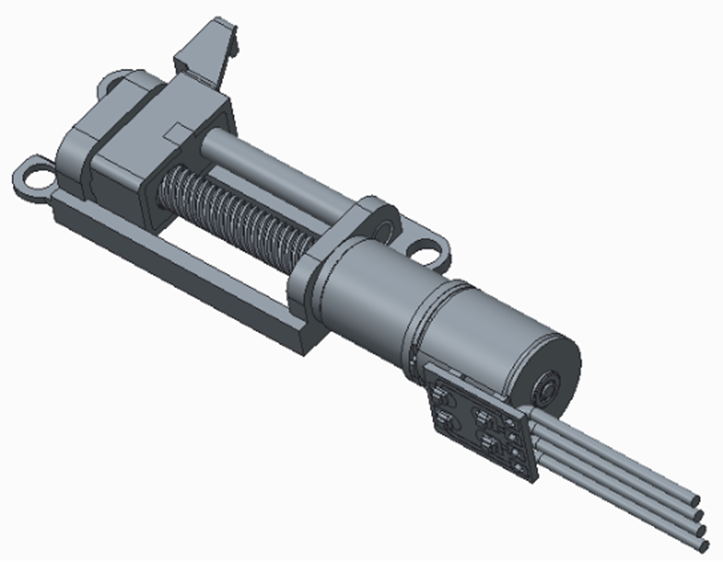

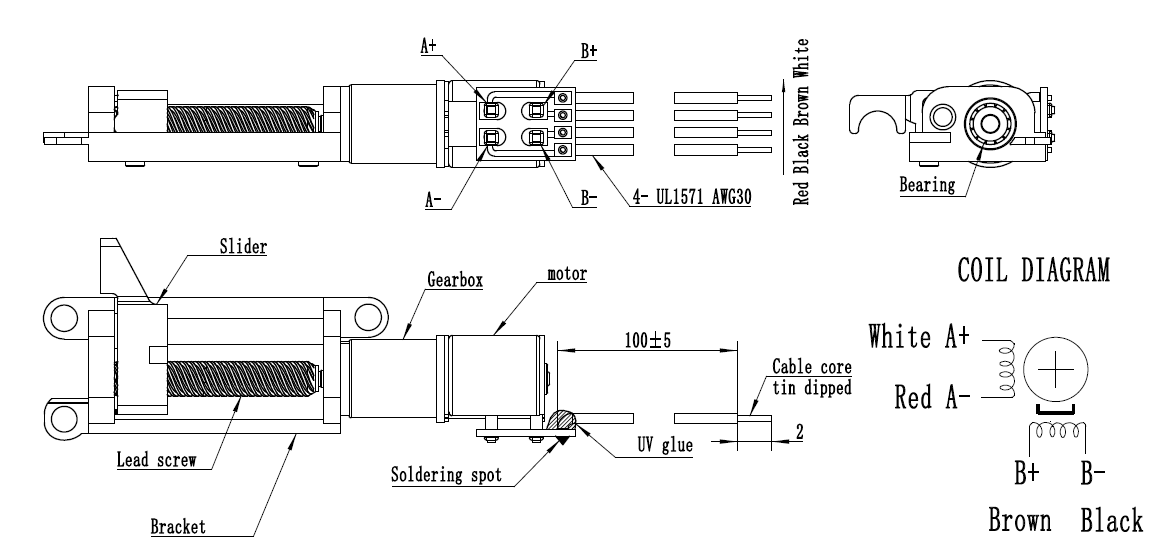

Txo gearbox deceleration:stepper lub cev muaj zog nruab nrog txo qis gearbox siv ua ke, stepper lub cev muaj zog tso zis siab ceev, qis torque ceev, txuas nrog txo qis gearbox, gearbox sab hauv txo iav teeb meshing kis tau tus mob tsim los ntawm kev txo qis, lub stepper lub cev muaj zog tso zis siab ceev yuav raug txo, thiab txhim khu kev sib kis torque kom ua tiav cov txiaj ntsig zoo tshaj plaws; Cov nyhuv txo yog nyob ntawm qhov txo qis ntawm lub gearbox, qhov ntau dua qhov txo qis, qhov me dua qhov tso zis ceev, thiab rov ua dua. Thiab vice versa.

Curve exponential tswj ceev:exponential nkhaus, nyob rau hauv lub software programming, thawj zaug xam lub sij hawm tas mus li nyob rau hauv lub computer nco, taw tes rau cov xaiv thaum ua hauj lwm. Feem ntau, kev ua tiav ntawm stepper motor acceleration thiab deceleration lub sij hawm ntawm 300ms los yog ntau tshaj. Yog hais tias koj siv lub sij hawm luv luv acceleration thiab deceleration, rau feem coob ntawm stepper motors, nws yuav nyuaj rau ua tiav high-speed tig ntawm stepper motors.

Encoder tswj deceleration:PID tswj raws li ib qho yooj yim thiab tswv yim tswj txoj kev, nyob rau hauv lub stepper tsav tsav tau txais ntau daim ntawv thov. Nws yog raws li tus nqi muab r (t) thiab qhov tseeb tso tawm tus nqi c (t) los tsim kev tswj kev sib txawv e (t), qhov sib txawv ntawm qhov proportional, ib qho thiab qhov sib txawv los ntawm kev sib xyaw ua ke ntawm kev tswj kom muaj nuj nqis, kev tswj cov khoom tswj. Daim ntawv siv ib qho kev sib koom ua ke sensor nyob rau hauv ob-theem hybrid stepper lub cev muaj zog thiab tsim ib qho kev hloov kho PI ceev tswj raws li qhov chaw ntes thiab vector tswj, uas muab cov yam ntxwv zoo nyob rau hauv kev ua haujlwm sib txawv. Raws li kev ua lej ntawm tus qauv stepper lub cev muaj zog, PID tswj qhov system ntawm stepper lub cev muaj zog yog tsim thiab PID tswj algorithm yog siv kom tau txais kev tswj kom muaj nuj nqis los tswj lub cev muaj zog mus rau qhov chaw teev tseg. Thaum kawg, nws tau txheeb xyuas los ntawm kev simulation tias kev tswj hwm muaj cov yam ntxwv zoo dynamic teb. PID maub los muaj qhov zoo ntawm cov qauv yooj yim, siab zog thiab kev ntseeg siab, tab sis nws tsis tuaj yeem cuam tshuam nrog cov ntaub ntawv tsis meej hauv lub cev.

Stepper lub cev muaj zog tuaj yeem phim nrog dab tsi reducer? Nyob rau hauv lub stepper lub cev muaj zog thiab gearbox xaiv pob yuav tsum tau them sai sai rau cov yam tseem ceeb, thiab hom gearbox yuav xaiv tau siv ua ke?

1. Yog vim li cas rau stepper lub cev muaj zog nrog reducer

Stepper lub cev muaj zog hloov qhov zaus ntawm lub stator theem tam sim no, xws li hloov lub tswv yim mem tes ntawm stepper tsav tsav Circuit Court, kom nws dhau los ua lub zog qis. Tsawg-ceev stepper lub cev muaj zog nyob rau hauv tos rau lub stepping hais kom ua, lub rotor yog nyob rau hauv ib tug nres, nyob rau hauv lub low-speed stepping, ceev fluctuations yuav loj heev, nyob rau hauv lub sij hawm no, xws li hloov mus rau high-ceev khiav lag luam, nws yuav daws tau qhov teeb meem ntawm ceev fluctuations, tab sis lub torque yuav tsis txaus. Ntawd yog, qhov qis qis yuav hloov pauv torque, thiab kev kub ceev yuav tsis txaus torque, yuav tsum tau siv lub reducer.

2. Stepper lub cev muaj zog feem ntau nrog reducer dab tsi

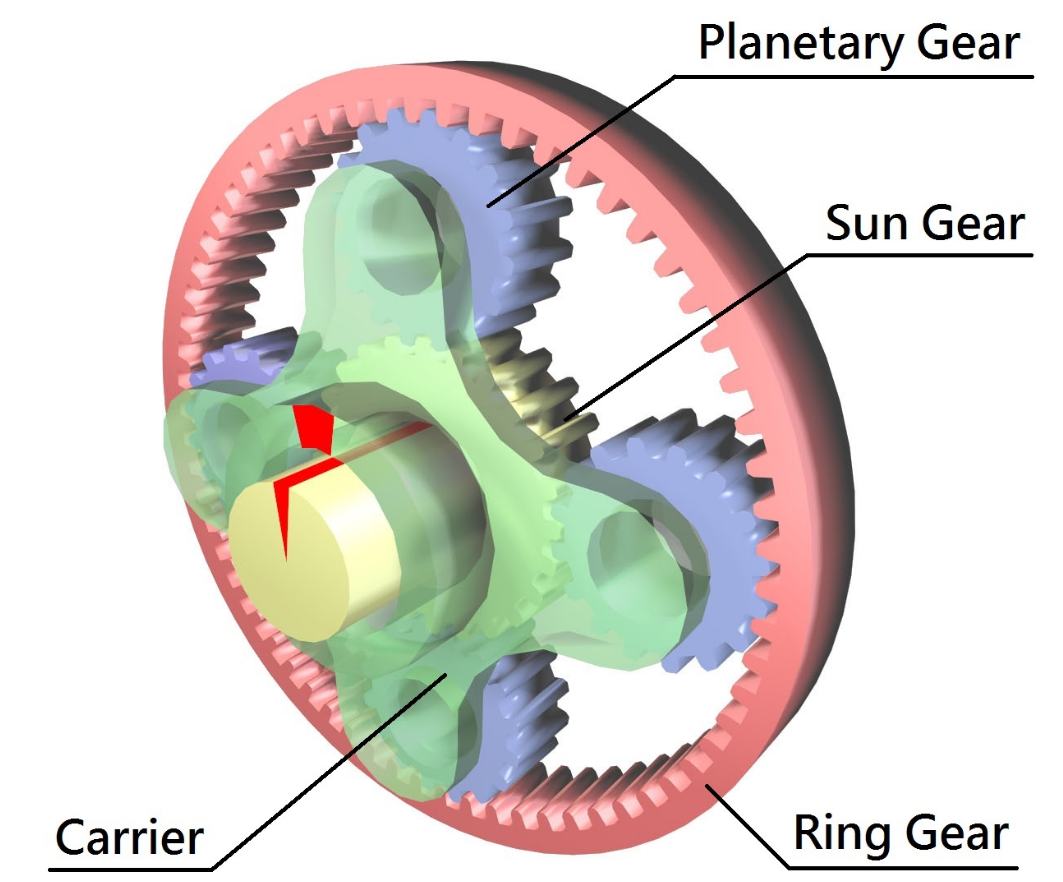

Reducer yog ib hom iav tsav, cab tsav, iav - cab tsav, uas yog nyob rau hauv ib tug nruj casing, feem ntau yog siv raws li ib tug reducer ntawm prime mover thiab lub tshuab ua hauj lwm, nruab nrab ntawm lub prime mover thiab lub tshuab ua hauj lwm los yog actuator kom phim lub ceev thiab torque kis tau tus mob; reducer muaj ntau yam, raws li hom kev sib kis tau muab faib ua iav reducer, iav iav reducer thiab planetary iav reducer. Raws li tus naj npawb ntawm cov theem sib kis tau muab faib ua ib theem thiab ntau theem reducer; Raws li cov duab ntawm lub iav tuaj yeem muab faib ua cylindrical iav reducer, bevel iav reducer thiab bevel-cylindrical iav reducer; Raws li daim ntawv sib kis tau tuaj yeem muab faib ua cov khoom siv hluav taws xob, shunt reducer thiab coaxial reducer. Stepper lub cev muaj zog sib dhos reducer yog planetary reducer, worm iav reducer, thaum uas tig mus iav reducer, filament iav reducer.

Yuav ua li cas txog stepper motor planetary reducer raug?

Qhov tseeb ntawm reducer tseem hu ua rov qab tshem tawm. Thaum cov zis kawg yog tsau thiab cov tswv yim kawg yog tig clockwise thiab counterclockwise los tsim lub rated torque +-2% torque ntawm cov zis kawg, muaj ib tug me me angular hloov ntawm lub input kawg ntawm lub reducer, thiab qhov no angular displacement yog rov qab clearance. Chav tsev yog "arc feeb", piv txwv li ib tug sixtieth ntawm ib degree. Qhov kev rov qab tshem tawm ib txwm muaj qhov tseem ceeb xa mus rau sab tso zis ntawm lub gearbox. Stepper lub cev muaj zog planetary reducer muaj siab rigidity, siab precision (ib theem tuaj yeem ua tiav hauv 1 feeb), kev sib kis tau zoo (ib theem hauv 97% -98%), siab torque / ntim piv, txij nkawm-dawb, thiab lwm yam.

Stepper lub cev muaj zog kis tau tus mob yog tsis kho, stepper lub cev muaj zog khiav lub kaum sab xis yog txiav txim siab tag nrho los ntawm cov kauj ruam ntev thiab tus naj npawb ntawm pulses, thiab tus naj npawb ntawm pulses tuaj yeem suav ua tiav, cov lej digital tsis yog lub tswv yim ntawm qhov tseeb, ib kauj ruam yog ib kauj ruam, ob kauj ruam yog ob kauj ruam. Qhov tseeb tam sim no uas tuaj yeem ua kom zoo dua yog qhov tseeb ntawm lub iav rov qab tshem tawm ntawm lub planetary gearbox.

- Spindle precision adjustment method:kev hloov ntawm lub planetary gearbox spindle rotational raug, yog hais tias lub machining yuam kev ntawm spindle nws tus kheej ua tau raws li qhov yuav tsum tau, ces qhov tseeb rotational ntawm lub reducer spindle yog feem ntau txiav txim los ntawm cov kabmob. Tus yuam sij rau kev kho qhov ntxaiv qhov tseeb yog kho cov kabmob clearance. Kev tswj xyuas qhov tsim nyog tshem tawm yog qhov tseem ceeb rau kev ua haujlwm ntawm cov khoom siv spindle thiab cov kabmob lub neej. Rau cov kabmob dov, thaum muaj kev tshem tawm loj, nws yuav tsis tsuas yog ua rau lub nra hnyav ntawm lub cev dov hauv kev coj ntawm lub zog, tab sis kuj ua rau muaj kev ntxhov siab loj tshwm sim nyob rau hauv cov kabmob sab hauv thiab sab nraud ntawm lub nplhaib sib tw, ua rau lub neej luv luv, kuj ua rau lub spindle centerline drift, yooj yim ua rau kev vibration ntawm spindle qhov chaw. Yog li ntawd, lub dov bearing hloov yuav tsum tau pre-loaded, tsim ib tug npaum li cas ntawm kev cuam tshuam nyob rau hauv lub bearing, thiaj li yuav tsim ib tug elastic deformation ntawm kev sib cuag ntawm lub dov lub cev thiab lub puab thiab sab nplhaib raceway, yog li txhim kho qhov nruj ntawm cov kabmob.

2. Kho qhov sib txawv txoj kev:planetary gearbox nyob rau hauv cov txheej txheem ntawm kev txav yuav tsim kev sib txhuam, ua rau muaj kev hloov pauv ntawm qhov loj me, cov duab thiab qhov zoo ntawm qhov chaw, thiab hnav, yog li ntawd qhov sib txawv ntawm cov khoom nrog nce, peb yuav tsum ua kom muaj qhov tsim nyog ntawm kev hloov kho kom ntseeg tau tias qhov tseeb ntawm cov txheeb ze txav ntawm qhov chaw.

3. Kev them nyiaj yuam kev:cov khoom lawv tus kheej ua yuam kev los ntawm kev sib dhos tsim nyog, kom qhov tshwm sim ntawm kev sib nrig sib offset thaum lub sij hawm tawg-nyob rau hauv lub sij hawm, los xyuas kom meej qhov tseeb ntawm cov khoom txav trajectory.

- Comprehensive them txoj kev:cov cuab yeej ntsia nrog lub reducer nws tus kheej ua rau kev ua tau raug pauv nrog kev hloov kho kom raug ntawm lub rooj ua haujlwm kom tshem tawm cov kev sib xyaw ua ke ntawm qhov raug ntawm qhov tsis raug.

Peb cov kev cai ua haujlwm 1.

Peb cov phiaj xwm kev cai 2.

Peb yog cov kws tshaj lij kev tshawb fawb thiab tsim cov koom haum tsom rau kev tshawb fawb thiab kev tsim kho lub cev muaj zog, tag nrhokev daws teeb meem rau kev siv lub cev muaj zog, thiab kev ua thiab kev tsim cov khoom siv lub cev muaj zog. Peb lub tuam txhab tau tshwj xeeb hauv kev tsim micro motors thiab accessories txij li xyoo 2011. Peb cov khoom tseem ceeb: me me stepper motors, iav motors, underwater thrusters thiab lub cev muaj zog tsav tsheb thiab controllers.

Peb cov khoom tau dhau ISO9000: 200, ROHS, CE thiab lwm yam ntawv pov thawj zoo. Peb lub tuam txhab tau thov rau ntau tshaj 20 patents, nrog rau 3 invention patents, uas yog dav siv nyob rau hauv cov nyiaj txiag machinery, chaw ua hauj lwm automation, hluav taws xob qhov rooj xauv, hluav taws xob curtains, ntse cov khoom ua si, tshuab kho mob, vending machine, kev lom zem khoom, advertising khoom, kev ruaj ntseg teeb pom kev zoo, theem teeb pom kev zoo, mahjong tshuab, khoom siv hauv chav da dej, khoom siv kho kom zoo nkauj hairdryer, nws pib qhov chaw, cov khoom ua si, cov cuab yeej hluav taws xob, cov khoom siv hauv tsev me, thiab lwm yam) cov tuam txhab paub zoo. Lub tuam txhab muaj zog technical force, cov cuab yeej siv siab heev, ua raws li "kev lag luam-taw qhia, zoo li lub hauv paus, lub koob npe nrov rau kev loj hlob" lub hom phiaj kev lag luam, ntxiv dag zog rau kev tswj hwm sab hauv, txhim kho cov khoom zoo.

Peb cuam tshuam nrog peb cov neeg siv khoom, mloog lawv cov kev xav tau thiab ua raws li lawv cov kev xav tau. Peb ntseeg hais tias lub hauv paus ntawm kev sib tw yeej-yeej yog cov khoom zoo thiab cov neeg siv khoom.

Thov koj xav tiv tauj peb!

Post lub sij hawm: Nov-24-2022