Thaum koj pib ua qhov project zoo siab - txawm tias nws tab tom tsim qhov tseeb thiab yuam kev dawb desktop CNC tshuab lossis lub caj npab ua haujlwm tsis zoo - xaiv cov khoom siv hluav taws xob zoo feem ntau yog tus yuam sij rau kev vam meej. Ntawm ntau qhov kev ua tiav, micro stepper motors tau dhau los ua qhov kev xaiv zoo tshaj plaws rau cov neeg tsim khoom, cov kws tsim khoom, thiab cov chaw tsim khoom vim lawv txoj kev qhib lub voj voog tswj, zoo heev torque tuav, thiab tus nqi qis.

Txawm li cas los xij, ntsib nrog ntau yam qauv thiab cov tsis yooj yim, yuav ua li cas xaiv lub micro stepper lub cev muaj zog rau koj cov neeg hlau lossis CNC tshuab? Kev xaiv qhov tsis ncaj ncees lawm yuav ua rau muaj qhov tsis raug, tsis muaj zog txaus, lossis txawm tias qhov project tsis ua haujlwm. Phau ntawv qhia no yuav ua raws li koj phau ntawv xaiv qhov kawg, coj koj ib kauj ruam los qhia meej txhua yam tseem ceeb thiab txiav txim siab zoo.

Kauj Ruam 1: Nkag siab cov ntsiab lus tseem ceeb - qhov sib txawv ntawm cov neeg hlau thiab CNC

Ua ntej yuav tshuaj xyuas ib qho kev txwv, koj yuav tsum qhia meej cov ntsiab lus tseem ceeb ntawm koj daim ntawv thov scenario rau lub cev muaj zog.

Cov phiaj xwm neeg hlau (xws li caj npab robotic, mobile robots):

Cov ntsiab lus tseem ceeb: dynamic teb, hnyav, loj, thiab efficiency. Cov pob qij txha ntawm cov neeg hlau yuav tsum nquag pib nres, hloov pauv ceev, thiab kev hloov pauv, thiab qhov hnyav ntawm lub cev muaj zog cuam tshuam rau tag nrho cov load thiab lub zog noj.

Cov ntsiab lus tseem ceeb: Ua tib zoo mloog ntau dua rau qhov torque ceev nkhaus (tshwj xeeb tshaj yog nruab nrab mus rau kev kub ceev torque) thiab lub zog rau qhov hnyav piv.

CNC tshuab cuab yeej (xws li 3-axis engraving tshuab, laser txiav tshuab):

Cov ntsiab lus tseem ceeb: thrust, smoothness, tswj torque, thiab precision. CNC tshuab cov cuab yeej yuav tsum tau kov yeej loj heev thaum lub sij hawm txiav los yog engraving, tswj cov lus tsa suab kom tsis txhob vibration, thiab yog txoj hauj lwm.

Cov ntsiab lus tseem ceeb: Ua tib zoo saib xyuas kev tswj lub zog ntawm qhov qis qis, micro kauj ruam daws teeb meem kom txo qis kev vibration, thiab lub cev muaj zog rigidity.

Kev nkag siab qhov sib txawv ntawm qhov tseem ceeb no yog lub hauv paus rau txhua qhov kev txiav txim siab xaiv tom ntej.

Kauj Ruam 2: Kev txhais ntawm Tsib Qhov Tseem Ceeb ntawm Micro stepper Motors

Nov yog tsib yam tseem ceeb uas koj yuav tsum tau them sai sai rau hauv phau ntawv qhia cov ntaub ntawv.

1. Loj thiab torque - lub hauv paus ntawm lub zog

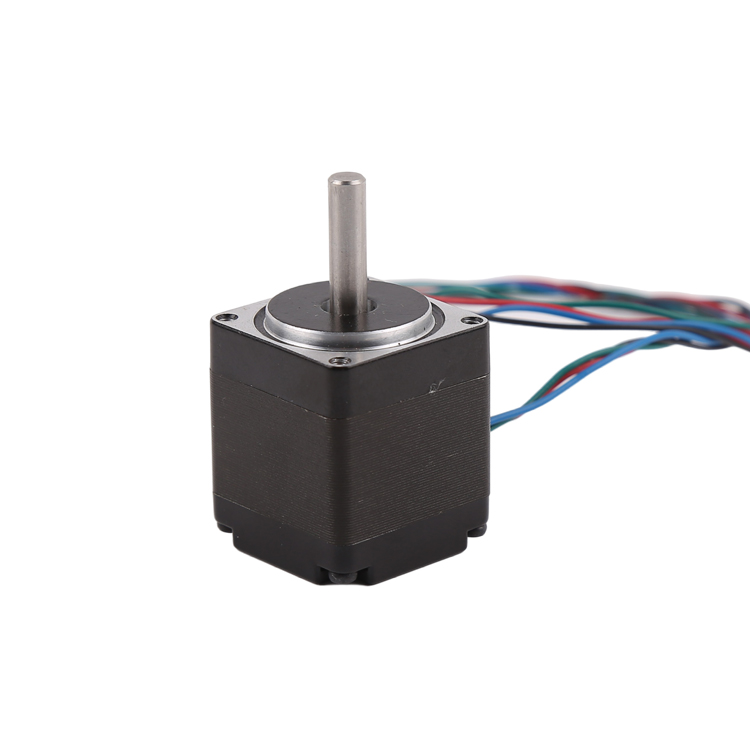

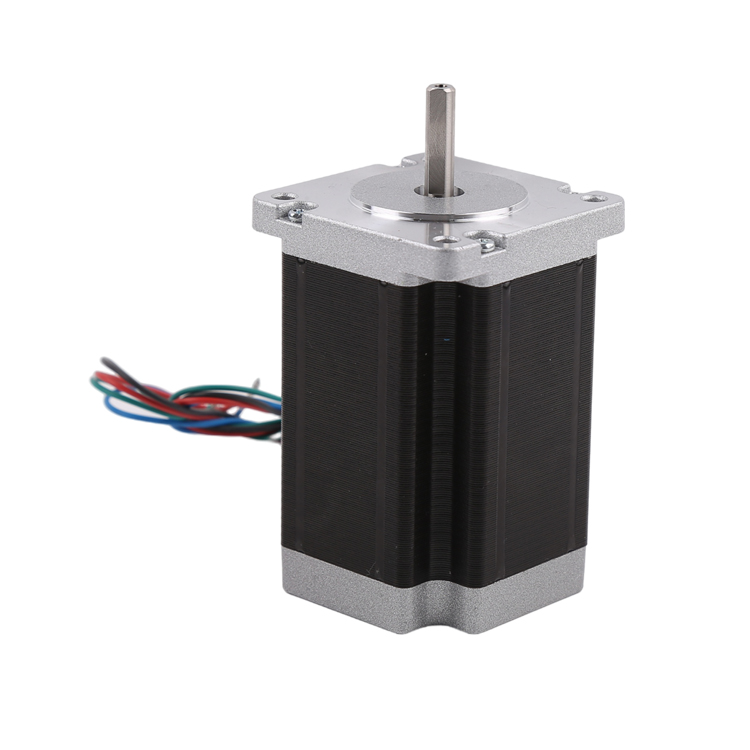

Loj (tswj lub hauv paus tooj): feem ntau qhia hauv millimeters (xws li NEMA 11, 17, 23). Tus txheej txheem NEMA txhais qhov ntev ntawm cov motors, tsis yog lawv qhov kev ua tau zoo. NEMA 17 yog qhov nrov tshaj plaws rau desktop robots thiab CNC, ua tiav qhov sib npaug zoo ntawm qhov loj thiab lub zog. Qhov me NEMA 11/14 yog tsim rau lub teeb load neeg hlau pob qij txha; Qhov loj dua NEMA 23 yog tsim rau cov cuab yeej siv tshuab CNC loj.

Tswj torque: Chav tsev yog N·cm lossis Oz·in. Qhov no yog qhov taw qhia tseem ceeb tshaj plaws rau kev ntsuas lub zog ntawm lub cev muaj zog. Rau CNC tshuab cuab yeej, koj xav tau txaus tuav torque los tiv thaiv txiav quab yuam; Rau cov neeg hlau, nws yog ib qho tsim nyog los xam qhov siab tshaj plaws torque xav tau rau cov pob qij txha.

Yuav ua li cas kwv yees qhov xav tau torque?

Rau cov cuab yeej siv tshuab CNC, txoj cai ntxhib ntawm tus ntiv tes xoo yog qhov torque uas tuaj yeem muab yam tsawg 20-30N (kwv yees li 2-3 kilograms) axial thrust yog xav tau. Qhov no yuav tsum tau hloov dua siab tshiab los ntawm cov hlau lead thiab efficiency ntawm cov ntsia hlau. Rau cov neeg hlau, kev suav cov dynamic nyuaj yuav tsum tau ua raws li caj npab ntev, thauj khoom hnyav, thiab acceleration. Nco ntsoov tawm ntawm torque margin ntawm 30% -50% txhawm rau tiv nrog qhov tsis paub tseeb xws li kev sib txhuam thiab inertia.

2.Lub kaum sab xis thiab qhov tseeb - tus ntsuj plig ntawm kauj ruam

Lub kaum sab xis: xws li 1.8 ° lossis 0.9 °. Lub cev muaj zog 1.8 ° tig ib zaug txhua 200 kauj ruam, thaum lub cev muaj zog 0.9 ° yuav tsum tau 400 kauj ruam. Qhov me dua lub kaum sab xis, qhov siab dua qhov tseeb ntawm lub cev muaj zog. A 0.9 ° lub cev muaj zog feem ntau yog smoother thaum khiav ntawm qis ceev.

3. Tam sim no thiab Voltage - Kev sib tw ntawm cov tsav tsheb

Theem tam sim no: Chav tsev yog Ampere (A). Qhov no yog qhov siab tshaj plaws tam sim no uas txhua theem winding ntawm lub cev muaj zog tuaj yeem tiv taus. Qhov no parameter ncaj qha txiav txim siab tsav twg koj yuav tsum xaiv. Cov zis tam sim no muaj peev xwm ntawm tus neeg tsav tsheb yuav tsum tau ua kom haum nrog lub cev muaj zog.

Voltage: Cov motors feem ntau yog ntsuas rau lawv qhov ntsuas hluav taws xob, tab sis qhov tseeb ua haujlwm voltage tuaj yeem siab dua qhov no (txiav txim siab los ntawm tus neeg tsav tsheb). Cov hluav taws xob siab dua pab txhim kho kev ua haujlwm siab ntawm lub cev muaj zog.

4. Inductance thiab high-ceev kev ua tau zoo - yam tseem ceeb uas yooj yim overlooked

Inductance yog qhov tseem ceeb cuam tshuam rau lub siab ceev torque ntawm lub cev muaj zog. Tsawg inductance motors tuaj yeem tsim tam sim no sai dua, ua rau muaj kev ua tau zoo ntawm kev kub ceev. Yog tias cov pob qij txha ntawm koj cov neeg hlau yuav tsum tau tig nrawm, lossis yog tias koj lub tshuab CNC xav kom tus nqi pub, koj yuav tsum tau ua ntej xaiv cov qauv uas tsis tshua muaj inductance.

5. hom ncej thiab txoj kab tawm - cov ntsiab lus ntawm kev sib txuas ntawm cov tshuab

Hom ncej: optical axis, ib qho tiaj tus ncej, ob chav tiaj tus ncej, iav ncej. D-hom trimming (ib lub tiaj tiaj tus ncej) yog qhov ntau tshaj plaws thiab tuaj yeem tiv thaiv kev sib txuas ntawm kev swb.

Txoj kev tawm mus: direct outgoing los yog plug-in. Txoj kev plug-in (xws li 4-pin lossis 6-pin aviation lub taub hau) yog qhov yooj yim rau kev teeb tsa thiab kev saib xyuas, thiab yog qhov kev xaiv tshaj lij.

Kauj Ruam 3: Tus khub tsis tseem ceeb - yuav ua li cas xaiv tus tsav tsheb stepper

Lub cev muaj zog nws tus kheej tsis tuaj yeem ua haujlwm thiab yuav tsum tau ua ke nrog tus tsav tsheb stepper. Qhov zoo ntawm tus neeg tsav tsheb ncaj qha txiav txim siab qhov kawg ntawm qhov system.

Microstep: Subdivide tag nrho cov kauj ruam mus rau ntau lub microsteps (xws li 16, 32, 256 microsteps). Lub luag haujlwm tseem ceeb ntawm micro stepping yog ua kom lub cev muaj zog ua haujlwm zoo heev, txo qis kev co thiab suab nrov, uas yog qhov tseem ceeb rau qhov zoo ntawm CNC tshuab cuab yeej.

Kev tswj tam sim no: Cov neeg tsav tsheb zoo heev muaj kev ua haujlwm tsis siv neeg ib nrab tam sim no. Tsis siv neeg txo tam sim no thaum lub cev muaj zog nyob ruaj ruaj, txo cov khoom siv hluav taws xob thiab kev siv hluav taws xob.

Common driver chips/modules:

Qib nkag: A4988- Tus nqi qis, haum rau cov haujlwm yooj yim neeg hlau.

Mainstream Xaiv: TMC2208/TMC2209- Txhawb kev tsav tsheb ntsiag to (StealthShop hom), ua haujlwm ntsiag to, yog qhov kev xaiv zoo tshaj plaws rau CNC tshuab cuab yeej, thiab muab kev tswj xyuas ntau dua.

Kev ua haujlwm siab: DRV8825/TB6600- muab kev txhawb nqa tam sim no thiab hluav taws xob ntau dua, haum rau cov ntawv thov uas xav tau lub zog ntau dua.

Nco ntsoov: tus neeg tsav tsheb zoo tuaj yeem ua kom muaj peev xwm ntawm lub cev muaj zog.

Kauj Ruam 4: Cov txheej txheem xaiv cov tswv yim thiab cov kev xav tsis zoo

Plaub kauj ruam xaiv txoj kev:

Txhais lub load: Kom meej meej txhais qhov siab tshaj plaws qhov hnyav, yuav tsum tau acceleration, thiab ceev uas koj lub tshuab yuav tsum tau txav.

xam torque: Siv lub laij lej torque online lossis cov qauv siv tshuab los ntsuas qhov xav tau torque.

Preliminary xaiv ntawm motors: Xaiv 2-3 tus qauv sib tw raws li qhov xav tau ntawm lub zog thiab qhov loj me, thiab sib piv lawv cov torque ceev nkhaus.

Match tsav tsheb: Xaiv qhov tsim nyog tus neeg tsav tsheb module thiab cov khoom siv hluav taws xob raws li theem tam sim no ntawm lub cev muaj zog thiab cov haujlwm uas yuav tsum tau ua (xws li mute, siab subdivision).

Common Misconceptions (Avoiding Pits Guide):

Misconception 1: Qhov loj dua lub torque, qhov zoo dua. Lub zog ntau dhau txhais tau hais tias lub cev muaj zog loj dua, hnyav dua, thiab siv zog ntau dua, uas yog qhov tshwj xeeb rau cov neeg hlau pob qij txha.

Misconception 2:Tsuas yog tsom rau kev tswj lub zog thiab tsis quav ntsej lub siab ceev torque. Lub cev muaj zog muaj lub siab torque ntawm qis ceev, tab sis raws li qhov ceev nce, lub torque yuav txo. Nco ntsoov xyuas daim ntawv qhia torque ceev nkhaus.

Misconception 3: Lub zog tsis txaus. Lub zog hluav taws xob yog lub zog ntawm qhov system. Lub zog tsis muaj zog tsis tuaj yeem tsav lub cev muaj zog ua haujlwm ntawm nws lub peev xwm. Lub zog hluav taws xob hluav taws xob yuav tsum yog tsawg kawg yog qhov nruab nrab ntawm qhov ntsuas hluav taws xob ntawm tus tsav tsheb, thiab lub peev xwm tam sim no yuav tsum muaj ntau dua 60% ntawm tag nrho cov theem tam sim no.

Kauj ruam 5: Kev txiav txim siab siab - Thaum twg peb yuav tsum xav txog kaw lub voj kaw lus?

Traditional stepper motors yog qhib-voj tswj, thiab yog hais tias lub load loj heev thiab ua rau lub cev muaj zog "poob kauj ruam", tus maub los yuav tsis paub txog nws. Qhov no yog qhov tsis txaus ntseeg rau cov ntawv thov uas xav tau 100% kev ntseeg tau, xws li kev lag luam qib CNC machining.

Lub kaw-loop stepper lub cev muaj zog ua ke nrog lub encoder nyob rau tom qab kawg ntawm lub cev muaj zog, uas tuaj yeem saib xyuas txoj haujlwm ntawm lub sijhawm thiab kho qhov yuam kev. Nws muab cov txiaj ntsig zoo ntawm lub zog siab rau stepper motors thiab kev ntseeg siab rau servo motors. Yog tias koj qhov project:

Tsis pub muaj kev pheej hmoo ntawm kev sib txawv.

Nws yog ib qho tsim nyog los siv tag nrho cov kev ua tau zoo tshaj plaws ntawm lub cev muaj zog (kaw-voj tuaj yeem muab kev nrawm dua).

Nws yog siv rau cov khoom lag luam.

Yog li, kev nqis peev nyob rau hauv kaw-voj stepper system yog tsim nyog.

Xaus

Xaiv qhov tsim nyog micro stepper lub cev muaj zog rau koj cov neeg hlau lossis CNC tshuab yog qhov kev tsim kho tshuab uas yuav tsum tau xav txog txhua yam, hluav taws xob, thiab kev tswj hwm. Tsis muaj 'zoo tshaj' lub cev muaj zog, tsuas yog lub cev muaj zog 'zoo tshaj'.

Txhawm rau txiav txim siab cov ntsiab lus tseem ceeb, pib los ntawm daim ntawv thov scenario, cov neeg hlau ua qhov tseem ceeb ntawm kev ua haujlwm zoo thiab qhov hnyav, thaum CNC tshuab cov cuab yeej tseem ceeb tshaj qhov zoo li qub torque thiab stability. Ua kom ruaj khov ntawm qhov tseem ceeb ntawm lub zog torque, tam sim no, thiab inductance, thiab muab nws nrog tus tsav tsheb zoo heev thiab lub zog txaus. Los ntawm kev taw qhia hauv kab lus no, Kuv vam tias koj tuaj yeem ntseeg siab ua qhov kev xaiv zoo tshaj plaws rau koj qhov project zoo tom ntej, kom ntseeg tau tias koj cov kev tsim ua tau zoo, muaj zog, thiab ntseeg tau.

Post lub sij hawm: Sep-25-2025